Keep up with our latest news

Carbon fiber is a game-changing material that has revolutionized industries around the world. Known for its incredible strength and lightweight, this advanced polymer is widely used in aerospace, motorsports, the military, and renewable energy sectors. With the introduction of fatcarbon®, a vibrant and visually striking version of colored carbon fiber, the material is now being used in high-end designs like knives, watches, jewelry, and automotive parts, where both performance and aesthetics are essential.

Composites are materials made by combining two or more different substances, where each component retains its own properties but, together, they create a material with enhanced characteristics. In most composites, one material acts as the matrix, holding the structure together, while the other serves as the reinforcement, providing added strength or stiffness.

For example, in carbon fiber composites carbon fibers act as the reinforcement, while the polymer resin forms the matrix. The result is a material that is much stronger and lighter than traditional metals. This makes composites highly versatile and useful across many industries.

Composites are favored for their ability to combine desirable properties such as strength, lightweight design, corrosion resistance, and heat resistance. They are used in a wide range of fields, including aerospace, automotive, sports equipment, and even luxury goods.

Carbon fiber is a lightweight, strong material made from thin strands of carbon atoms bonded together. Each strand is thinner than human hair, but when woven or combined with materials like resin, it forms a composite that is both — highly durable and lightweight. It’s used in industries where the balance between strength and weight is critical, like aerospace, automotive, outdoor tools, watchmaking, and jewelry.

Carbon fiber starts with a precursor material, typically polyacrylonitrile (PAN). This material is heated to over 1,000°C in an oxygen-free environment a procedure known as carbonization. This process removes everything except carbon, leaving behind tightly bonded carbon atoms that form rigid crystals. These crystals are spun into fine fibers, which can then be woven or molded into different forms depending on the application.

For more details, check out this article: The Making of Carbon Fiber.

Thanks to its high strength, low weight, and corrosion resistance, carbon fiber is used in a wide range of industries, including:

fatcarbon® is an advanced carbon fiber composite that offers both the functional benefits of traditional carbon fiber and the visual appeal of bold colors and intricate patterns. Unlike standard carbon fiber, which typically appears in black or gray, fatcarbon® is made by integrating colored polymers or even metals and layering materials during the manufacturing process to create visually stunning, unique patterns.

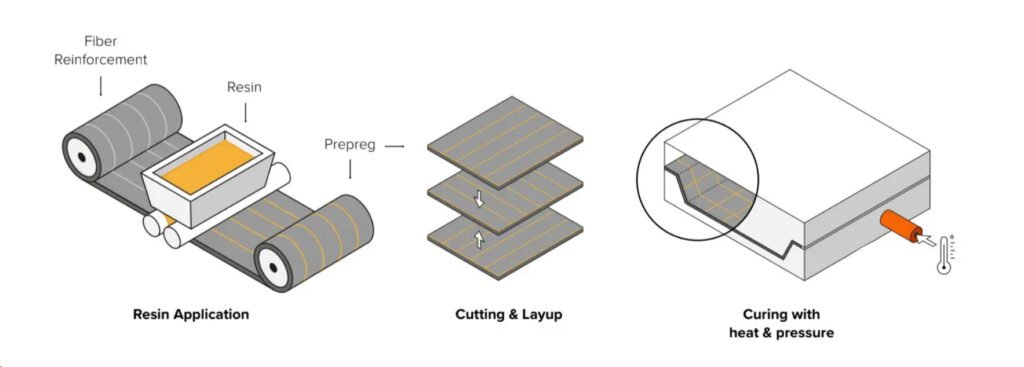

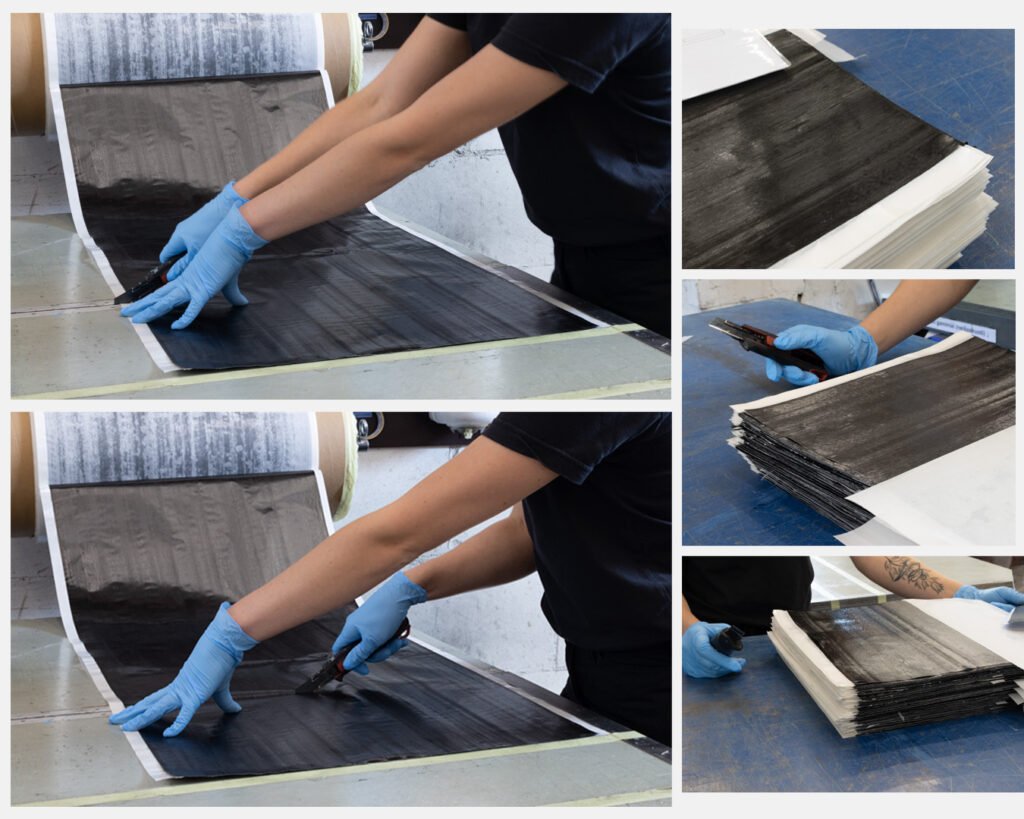

The production process of fatcarbon® involves meticulously arranging layers of carbon fiber with colored polymers or even metals, which are then pressed and heated (press molding process, also commonly known as carbon fiber forging — check the Wikipedia page for more on this topic), which allows the layers to bond into a solid composite. This process results in distinctively marbled, striped, or cosmic patterns, giving each piece of fatcarbon® a one-of-a-kind, galaxy-inspired look. These patterns, along with bright colors like blue, red, and gold, give fatcarbon® its signature aesthetic appeal, making it a standout material in high-end design.

fatcarbon® not only offers a unique aesthetic appeal but also retains all the high-performance characteristics of carbon fiber composites. Constructed with a 0/90-degree unidirectional layup of standard modulus carbon fiber and epoxy resin, fatcarbon® is lightweight, exceptionally strong, and resistant to environmental factors like corrosion, UV exposure, and temperature fluctuations. The 38% resin content ensures optimal fiber adhesion and contributes to the mechanical integrity of the material. Additionally, its UV resistance is crucial, as it prevents degradation or fading when exposed to sunlight, thereby preserving both its structural strength and vibrant colors over time. This combination of durability and style makes fatcarbon® perfect for products like knives, watches, jewelry, and automotive parts, where both form and function are essential. The unidirectional fibers in a 0/90 layup provide excellent strength in multiple directions without compromising the unique patterns and ensuring that even intricate designs maintain exceptional performance.

Fun Fact: The tensile strength of the carbon fibers used in fatcarbon® colored composites can reach up to 4,900 MPa, making them about 10 times stronger than steel while weighing only a fraction of it!

fatcarbon® is available in various forms to suit different design needs such as sheets, blocks up to 150 mm thick, rods, and even premade blanks. Whether you’re using manual tools or CNC machines, fatcarbon® is easy to work with. For cutting, tools like bandsaws, manual mills, or the high-precision machines such as water jet cutters and CNC mills can be used to achieve clean and accurate cuts. After shaping, a sandpaper or tumbling media is typically used to finish and smooth the surfaces, resulting in a polished, visually striking appearance. For more information on how to finish fatcarbon® parts for a striking look, read our blog post: Improve Fatcarbon Surface Finish Parts.

One of the key reasons for the growing popularity of fatcarbon® is its wide array of colors and patterns. Common patterns include marbled designs that mimic natural phenomena like Dark Matter, as well as geometric patterns like woodgrain effects. These patterns are not merely superficial; they are embedded throughout the material, adding depth and creating a true 3D appearance in the designs. The bold colors add another layer of customization and offer designers endless possibilities for creativity.

The combination of strength, lightweight, and striking aesthetics in fatcarbon® makes it the perfect material for high-end design applications. In knives, for example, it offers the toughness required for a durable handle while making each piece visually unique. In luxury watches, fatcarbon® provides a futuristic look that remains lightweight and comfortable to wear. When used in jewelry, colored carbon fiber composites bring a modern, bold statement while maintaining durability. In automotive parts, it combines high performance with a luxury feel, creating custom trims and panels that are both functional and stunning.

At fatcarbon®, we are committed to sustainability and minimizing our environmental impact, aligning with modern eco-conscious practices. A key example of this is our Dark Matter series, where we repurpose leftover carbon fiber from various industries, including aerospace and automotive. By reclaiming this high-quality material, we reduce waste and give it new life in high-end design applications.

Furthermore, our workshop and office are powered entirely by renewable energy sources, including wind and solar, ensuring that our manufacturing process has a minimal carbon footprint. In line with our commitment to sustainability, we also implement lean manufacturing strategies. This involves minimizing waste at every stage of production, optimizing our processes to use as few resources as possible, without compromising the quality or integrity of our products.

fatcarbon® represents the next step in color carbon fiber composites innovation. Its remarkable ability to combine high performance with striking design sets it apart as one of the most exhilarating materials on the market today. As industries increasingly embrace fatcarbon®, it’s evident that this is not merely a trend but a transformative solution for visionary designers eager to redefine the limits of what’s possible with carbon fiber composites.